china pearl mica factories

Exploring China's Pearl Mica Factories A Shimmering Industry

China has long been recognized as a global hub for mining and manufacturing, and among its diverse array of industries, pearl mica stands out as a unique and fascinating sector. The production of pearl mica, a natural mineral noted for its shimmering and iridescent qualities, plays an important role in various applications ranging from cosmetics to automotive finishes. This article delves into the operations of pearl mica factories in China, examining their processes, products, and the market demand driving their success.

The Essence of Pearl Mica

Pearl mica, scientifically known as muscovite or phlogopite, is a mineral that possesses distinctive physical properties, including its layered structure and reflective sheen. It is often used as a pigment in cosmetics such as eye shadows, highlighters, and nail polishes, as well as in industrial applications like paints, plastics, and coatings. The iridescent nature of pearl mica makes it a favored choice for enhancing the aesthetic appeal of products, leading to a growing demand in various industries.

China’s Pearl Mica Industry

China is one of the leading producers of pearl mica, with numerous factories dedicated to extracting and processing this valuable mineral. The country's rich geological resources provide an abundance of mica deposits, particularly in regions like Liaoning, Jiangsu, and Zhejiang. These regions have attracted investment in mica mining and processing facilities, helping to establish a robust supply chain for both domestic consumption and international export.

Manufacturing Processes

The production of pearl mica involves several key steps, including mining, processing, and finishing.

1. Mining The extraction of mica is typically done through open-pit mining, which allows for the efficient removal of large volumes of mineral with minimal environmental disruption. Workers carefully extract mica from the earth, ensuring that the integrity of the crystals is preserved for later processing.

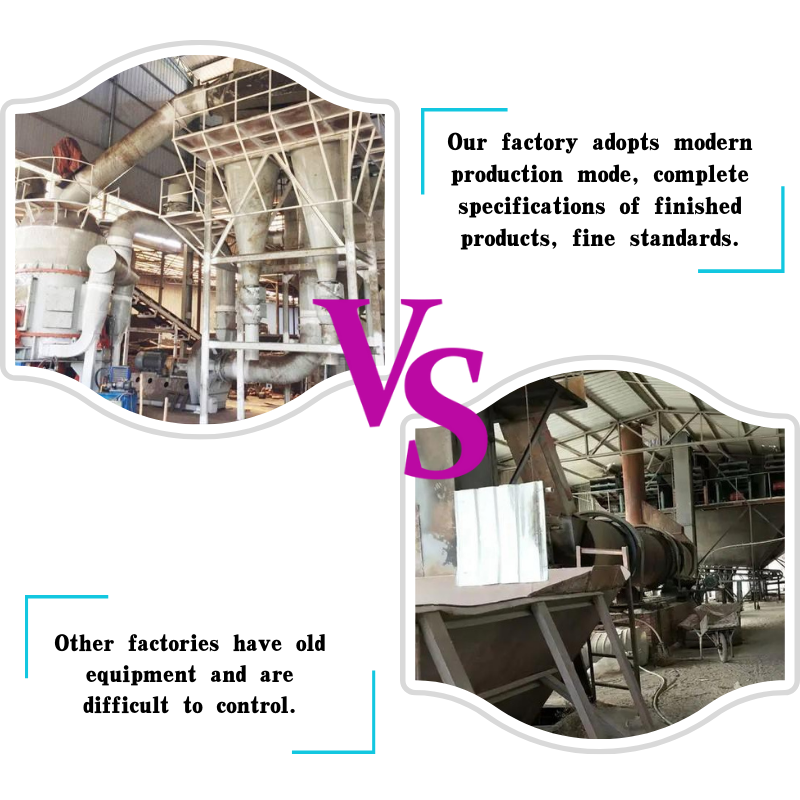

china pearl mica factories

2. Processing Once mined, the mica undergoes rigorous processing to ensure its purity and color quality. This includes grinding the mica into fine particles, sorting by size, and sometimes coating it with specialized chemicals to enhance its reflective properties. Factories employ advanced technologies and techniques to achieve consistent quality, which is crucial for meeting industry standards.

3. Quality Control Quality control is paramount in pearl mica production. Factories conduct numerous tests to verify the mineral's purity, reflection, and particle size distribution. This attention to detail ensures that the final product meets the stringent requirements of clients in the cosmetics and industrial sectors.

Applications and Market Demand

The demand for pearl mica continues to rise, propelled by the expanding beauty industry and the increasing use of decorative elements in interior design and manufacturing. In cosmetics, the trend toward natural and mineral-based products has further fueled interest in pearl mica. Brands are constantly looking for innovative ways to enhance their offerings with eye-catching finishes, driving the need for high-quality mica particles.

Moreover, as consumers become more conscious of sustainability, many manufacturers are seeking ethically sourced mica. Chinese factories have taken steps to comply with international standards and certifications, ensuring that their mica is produced responsibly. This focus on ethical mining and processing practices is positioning Chinese pearl mica as a desirable choice for companies worldwide.

Challenges and Opportunities

While the pearl mica industry in China flourishes, it is not without challenges. Issues such as environmental concerns surrounding mining practices and fluctuating market prices can pose risks to sustainability. However, this also presents opportunities for innovation and improvement within the industry. Factories are exploring eco-friendly practices, such as waste reduction and recycling initiatives, to mitigate their environmental impact.

Conclusion

The pearl mica factories in China represent a vibrant sector of the mineral production industry, contributing significantly to global markets. With their rich resources, advanced technologies, and commitment to quality, these factories play a crucial role in supplying a material that continues to captivate consumers and manufacturers alike. As market trends evolve and sustainability becomes more critical, the future of China's pearl mica industry will likely see exciting developments, fostering growth and innovation while meeting the demands of a sustainable world.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025