metakaolin factories

Understanding the Role of Metakaolin in Modern Industries

Metakaolin, an innovative material derived from the calcination of kaolinite clay, has garnered significant attention across various industries due to its unique properties and versatile applications. This white powder is not only prized for its performance-enhancing capabilities but also for its environmental benefits. In this article, we will explore the various aspects of metakaolin production, its multifaceted uses, and the future of metakaolin factories.

The Production of Metakaolin

The manufacturing process of metakaolin involves heating kaolinite clay to temperatures between 600 to 800 degrees Celsius. This thermal treatment results in the dehydroxylation of the clay, converting it into a highly reactive pozzolanic material. The exact temperature and duration of the heating process significantly influence the quality and reactivity of the final product. High-quality metakaolin factories employ precise control over these variables to ensure consistency and high performance in the end product.

The raw materials for metakaolin come from kaolin deposits, which are found in many regions globally. Once the kaolin is mined, it undergoes various stages of processing, including crushing, grinding, and purification, before it is subjected to calcination. Meeting environmental standards during production is crucial, as the calcination process can lead to emissions of greenhouse gases. Therefore, leading metakaolin factories are continually exploring ways to minimize their carbon footprint through improved energy efficiency and adopting sustainable practices.

Applications of Metakaolin

Metakaolin’s remarkable properties make it a valuable additive in multiple applications, particularly in the construction and manufacturing sectors. One of the most notable uses is as a mineral admixture in cement and concrete. When incorporated into concrete mixtures, metakaolin enhances strength, durability, and resistance to chemical attacks. This is due to its pozzolanic nature, which allows it to react with calcium hydroxide produced during cement hydration to form additional cementitious compounds.

metakaolin factories

Moreover, metakaolin has a lower carbon footprint than traditional materials, making it an environmentally friendly alternative. Its use in concrete not only extends the lifespan of structures but also reduces overall energy consumption during production. This aligns with the increasing focus on sustainable practices within the construction industry.

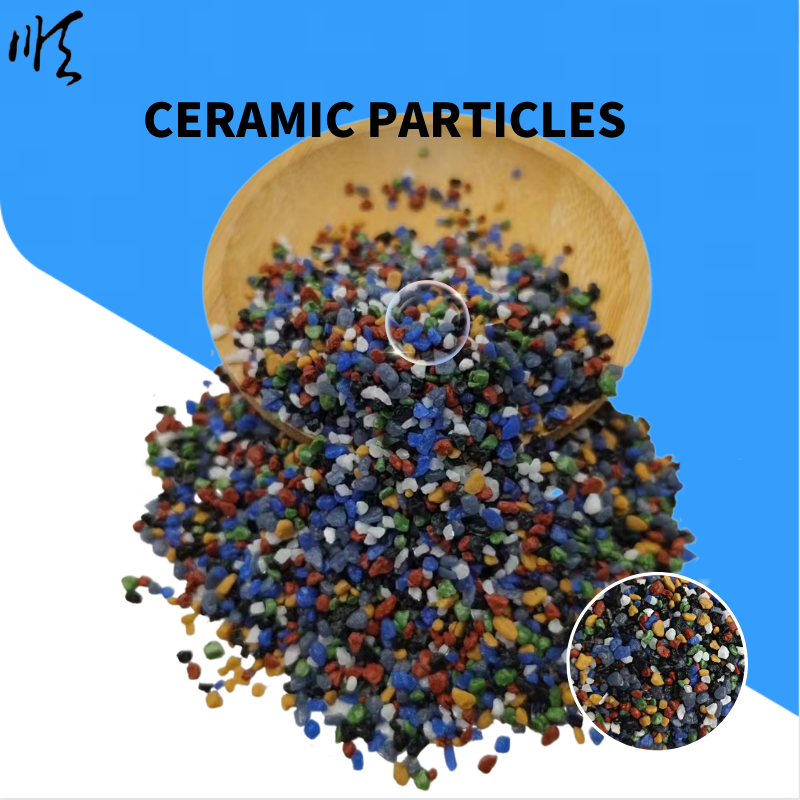

Apart from construction, metakaolin finds applications in ceramics, paints, and coatings. The fine particle size and absorbent nature of metakaolin make it an excellent filler, enhancing the mechanical properties and aesthetic qualities of these products. Additionally, in the field of geotechnical engineering, metakaolin is used to improve soil stabilization and enhance the load-bearing capacity of structures.

The Future of Metakaolin Factories

As the demand for sustainable construction materials continues to rise, metakaolin factories are poised for significant growth. There is growing awareness of the environmental issues related to traditional cement production, which accounts for a substantial portion of global carbon emissions. As a result, industries are increasingly seeking alternatives like metakaolin that can contribute to more sustainable building practices.

Innovation and technology will play a critical role in the evolution of metakaolin manufacturing. Advances in automation and data analysis are expected to optimize production processes, enhance product quality, and reduce operational costs. Additionally, research is ongoing to develop new metakaolin-based composites that can be utilized across various industries, further expanding its application range.

In conclusion, metakaolin is not just a niche material; it is a key player in the future of sustainable industrial practices. As metakaolin factories evolve to meet the challenges of modern production while minimizing their environmental impact, the material’s utilization across various sectors will likely continue to expand. With its proven benefits in construction, ceramics, and beyond, metakaolin represents a promising pathway toward more sustainable industrial practices, making it an essential focus for manufacturers and researchers alike. The journey of metakaolin and its factories is just beginning, and its impact on future industries could be revolutionary.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025