Tailored Iron Oxide Pigments for Versatile Applications and Enhanced Performance

The Versatility and Benefits of Custom Iron Oxide Pigments

Iron oxide pigments have become increasingly popular in various industries due to their versatility, durability, and eco-friendliness. As the world moves towards sustainable materials and practices, custom iron oxide pigments are emerging as an essential component in paints, coatings, construction materials, and more. This article delves into the characteristics, applications, and advantages of custom iron oxide pigments, highlighting why they are a preferred choice for manufacturers and consumers alike.

What are Iron Oxide Pigments?

Iron oxide pigments are natural or synthetic compounds composed primarily of iron oxide. They are available in a wide range of colors, including red, yellow, brown, and black. This variety arises from the different oxidation states of iron in the pigments. The hues can be combined to create a broader spectrum of colors, allowing manufacturers to achieve specific aesthetic requirements in their products. Moreover, these pigments possess excellent lightfastness, heat stability, and weather resistance, making them suitable for both indoor and outdoor applications.

Customization and Its Importance

The demand for personalized solutions in manufacturing processes has led to the rise of custom iron oxide pigments. Customization allows manufacturers to tailor pigments based on specific requirements, such as particle size, color shade, opacity, and formulation. This modification can significantly enhance the performance of the pigments in various substrates, improving color retention and overall product longevity.

Custom iron oxide pigments also address the unique needs of different industries. For example, the construction sector requires pigments that can withstand harsh environmental conditions, while the cosmetics industry demands pigments that are safe for skin contact and provide vibrant colors. By providing custom solutions, manufacturers can ensure their products meet industry standards and consumer expectations.

Applications of Custom Iron Oxide Pigments

The versatility of custom iron oxide pigments means they can be utilized in numerous applications

1. Paints and Coatings Iron oxide pigments are widely used in paints and coatings due to their excellent color stability and durability. They provide not only aesthetic appeal but also function as UV filters, protecting surfaces from sun damage.

2. Construction Materials In the construction industry, these pigments are often used in cement, concrete, and tile production, providing rich colors that enhance aesthetics while ensuring longevity and versatility in materials.

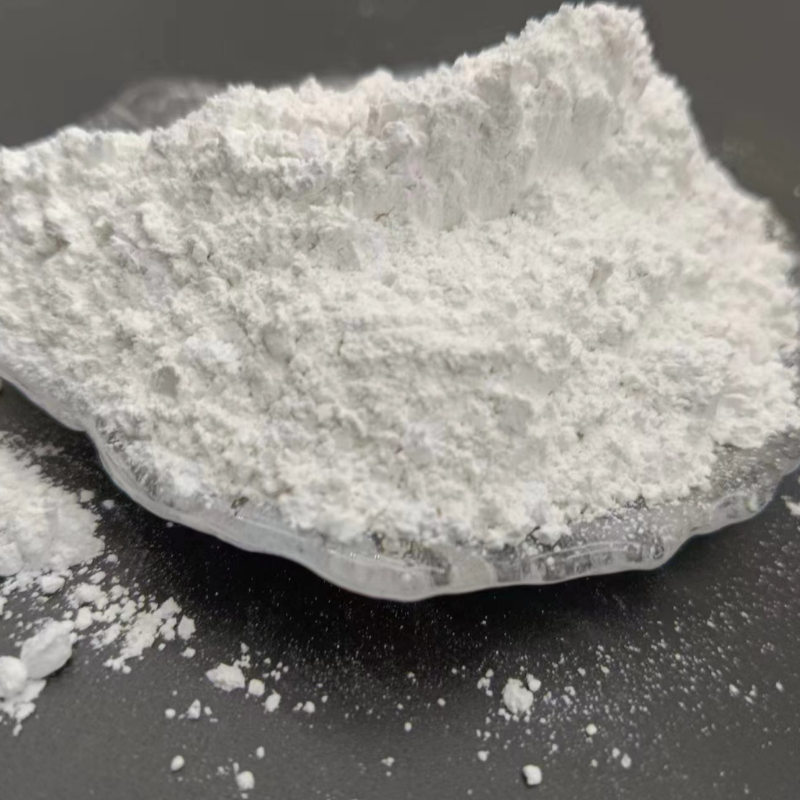

custom iron oxide pigments

3. Plastics Custom iron oxide pigments are utilized in the plastics industry to impart color to various products, from toys to automotive parts. Their heat stability ensures that colors remain vibrant even when exposed to high temperatures during processing.

4. Cosmetics and Personal Care Due to their non-toxic nature, iron oxide pigments are commonly found in cosmetic products, offering safe coloring options for foundations, eye shadows, and other makeup items.

5. Agricultural Applications In agriculture, these pigments are used as colorants in fertilizers and soil amendments, which can improve product identification and branding.

Benefits of Custom Iron Oxide Pigments

The shift towards custom iron oxide pigments brings a myriad of benefits

- Eco-Friendly Options Many iron oxide pigments are derived from natural sources and are non-toxic, making them suitable for environmentally-conscious consumers. Their inorganic nature also means they don’t release harmful substances, contributing to safer products.

- Cost-Effectiveness Custom formulations can lead to reduced waste and optimized production processes. By using pigments tailored for specific applications or colors, companies can better utilize raw materials and decrease costs.

- Enhanced Performance Custom iron oxide pigments can be engineered to improve performance metrics, such as UV resistance, heat stability, and color retention. This ensures that end products not only look good but also perform well in their intended environments.

Conclusion

The growing trend of custom iron oxide pigments reflects the evolving needs of various industries seeking both functionality and aesthetic appeal. With their versatility, durability, and eco-friendly characteristics, these pigments establish themselves as a crucial component in a range of products from construction materials to cosmetics. As manufacturers continue to innovate and tailor their solutions, we can expect custom iron oxide pigments to play an increasingly significant role in enhancing product quality and sustainability across various sectors.

Share

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025