talc powder manufacturers

The Essential Guide to Talc Powder Manufacturers Quality, Applications, and Beyond

Talc powder, widely known for its soft texture and unique properties, is a versatile mineral used in various industries such as cosmetics, pharmaceuticals, plastics, and ceramics. This mineral, composed primarily of magnesium, silicon, and oxygen, is a hydrous magnesium silicate that serves multiple applications, making it a significant commodity in the manufacturing sector. As industries continuously evolve, the demand for high-quality talc powder has surged, resulting in numerous manufacturers emerging in the market. In this article, we will explore the landscape of talc powder manufacturers, their quality standards, applications, and the factors to consider when selecting the right supplier.

What is Talc Powder?

Talc powder's unique characteristics, including its softness, hydrophobicity, and chemical inertness, make it a preferred material in many applications. Its use as a lubricant, anti-stick agent, and filler enhances the performance of products in various fields. For instance, in cosmetics, talc provides a smooth texture and absorbs moisture, making it a key ingredient in products such as face powders, foundations, and baby powder.

Applications of Talc Powder

1. Cosmetics and Personal Care Talc is extensively used in the cosmetics industry due to its absorbent properties. It helps to reduce skin moisture and provides a silky feel to formulations. Additionally, it acts as a bulking agent, providing a better spreadability and texture in powders and foundations.

2. Pharmaceuticals In the pharmaceutical industry, talc is used as an excipient in tablet formulations, helping to improve the flow properties of the powders and aiding in the manufacturing process. Its role as an anti-caking agent is also critical, ensuring that tablets maintain their integrity and effectiveness.

3. Plastics and Polymers Talc powder enhances the properties of plastics, improving their stiffness, thermal stability, and impact resistance. It is commonly used in polypropylene and polyethylene products, making talc a key additive in the plastic manufacturing process.

4. Ceramics In ceramic production, talc contributes to the strength and durability of the finished products. It lowers the firing temperature, enhances the workability of clay, and improves the finished product's aesthetic qualities.

5. Paper Manufacturing Talc is used as a filler in paper products, enhancing their brightness, opacity, and smoothness. It also aids in the paper-making process by improving the drainage and sheet formation.

Quality and Standards in Talc Powder Manufacturing

The quality of talc powder is paramount to its performance in various applications. Talc manufacturers must adhere to stringent quality control processes to ensure that their products meet industry standards. This includes

talc powder manufacturers

- Purity High-quality talc should contain a high percentage of pure talc, with minimal impurities

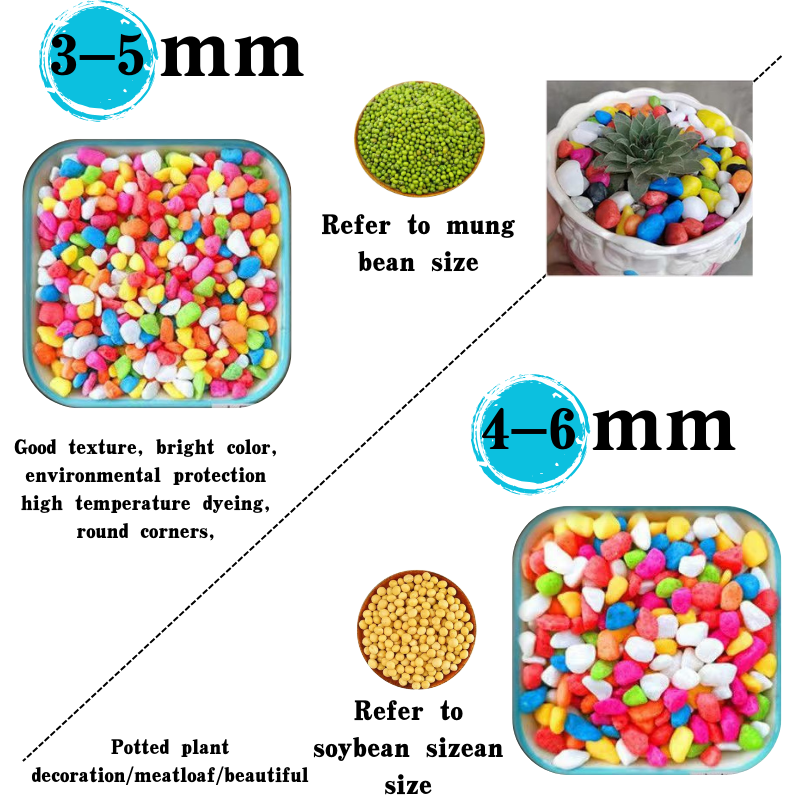

. Manufacturers must conduct thorough testing to verify the mineral composition.- Particle Size Distribution The effectiveness of talc powder often depends on its particle size. Consistent particle size distribution is crucial for applications in cosmetics and pharmaceuticals, where product feel and formulation stability are essential.

- Safety and Certification Given the scrutiny surrounding talc's safety, particularly in cosmetics, reputable manufacturers obtain certifications from health and safety regulatory bodies. This ensures that their products are free from harmful contaminants and safe for consumer use.

Choosing the Right Talc Powder Manufacturer

When selecting a talc powder manufacturer, businesses should consider various factors, including

1. Reputation and Experience Established manufacturers with a proven track record are often more reliable in terms of quality and consistency.

2. Quality Assurance Processes Look for manufacturers that prioritize quality control and obtain relevant certifications ensuring product safety and efficacy.

3. Customization Options Some manufacturers offer tailored solutions to meet specific industry needs. Be sure to inquire about customization possibilities, such as particle size and specific grades of talc.

4. Customer Support A manufacturer that provides excellent customer service and support can assist in troubleshooting any issues related to product application and performance.

Conclusion

Talc powder manufacturers play a crucial role in supplying high-quality materials for various applications. With its diverse usage in cosmetics, pharmaceuticals, plastics, and more, talc remains a vital ingredient in numerous products consumers use daily. By understanding the importance of quality and the factors to consider when selecting a manufacturer, businesses can ensure they partner with suppliers that meet their needs and contribute to their success in the ever-competitive marketplace.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025