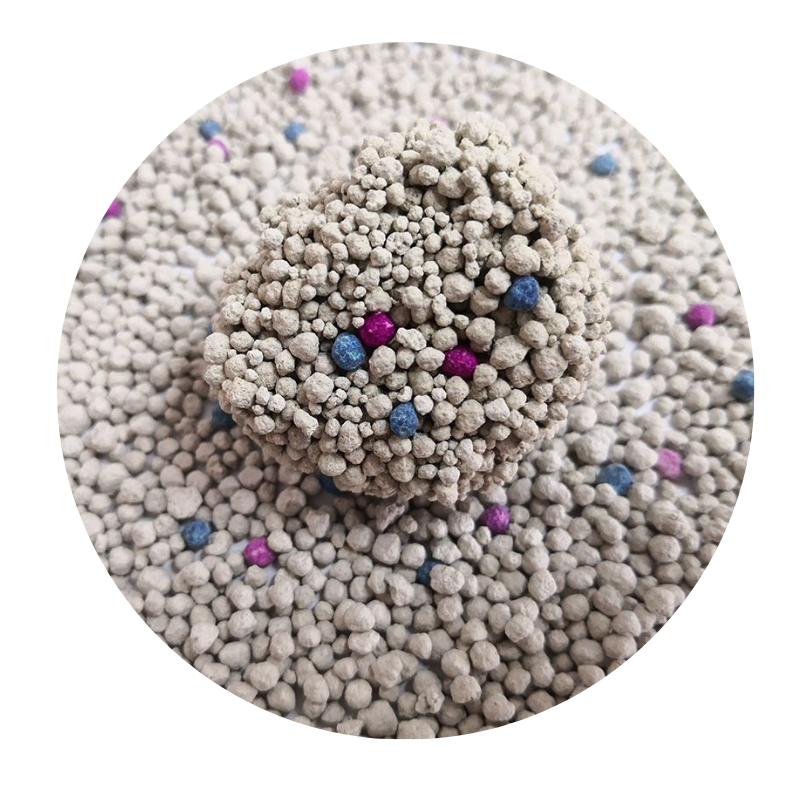

OEM Suppliers for Quality Bentonite Clay Products and Custom Manufacturing Solutions

Understanding OEM Buying for Bentonite Clay A Comprehensive Guide for Manufacturers

As the demand for bentonite clay skyrockets, manufacturers are increasingly looking towards Original Equipment Manufacturer (OEM) buying strategies to enhance their competitiveness in the market. Bentonite clay, known for its unique properties such as swelling, water absorption, and adsorption, has applications across various industries including construction, cosmetics, agriculture, and more. This article will delve into the significance of OEM buying for bentonite clay manufacturers, exploring its benefits, challenges, and best practices.

What is OEM Buying?

OEM buying refers to the practice where a company purchases products or components from another manufacturer to further rebrand or integrate them into their own finished products. In the context of bentonite clay, manufacturers may source the raw material from specialized suppliers before processing it for specific applications, maximizing both efficiency and resource allocation.

Benefits of OEM Buying for Bentonite Clay Manufacturers

1. Cost Efficiency One of the primary advantages of OEM buying is the potential for significant cost savings. By outsourcing the sourcing of bentonite clay, manufacturers can reduce overhead costs associated with mining, processing, and quality control. This allows companies to allocate resources more effectively, focusing on innovation and product development.

2. Quality Assurance Working with established OEM suppliers often ensures a higher consistency in the quality of bentonite clay. Reputable suppliers understand the importance of complying with quality standards, which leads to better performance in end-products. A careful selection of OEM partners can enhance a manufacturer's overall product quality and reliability.

3. Access to Expertise OEM suppliers often come with extensive industry knowledge and technical expertise. This allows bentonite clay manufacturers to leverage the latest advancements in processing technologies and market trends, enabling them to stay ahead of the competition.

4. Scalability OEM buying provides flexibility and scalability for manufacturers. As demand for bentonite clay fluctuates, manufacturers can easily adjust their purchasing volumes without the burden of maintaining extensive in-house production capabilities.

5. Faster Time-to-Market By relying on OEM partners for raw materials, manufacturers can significantly reduce their lead times. This rapid sourcing capability allows them to respond quickly to market trends and customer demands, fostering agility in the production process.

Challenges of OEM Buying for Bentonite Clay Manufacturers

Despite its numerous benefits, OEM buying also presents certain challenges that manufacturers must navigate carefully

oem buy bentonite clay manufacturers

1. Quality Control Risks While partnering with an OEM can improve quality, it can also pose risks if the supplier does not meet agreed-upon standards. Manufacturers must implement stringent quality control measures to ensure that the sourced bentonite clay meets their specifications.

2. Supply Chain Vulnerability Dependence on external suppliers can lead to supply chain disruptions. Economic fluctuations, geopolitical tensions, and natural disasters can affect the availability of bentonite clay. Manufacturers should develop robust contingency plans to mitigate these risks.

3. Intellectual Property Concerns Working with OEM suppliers can raise concerns regarding the protection of intellectual property. Manufacturers need to ensure that agreements with suppliers include clauses that safeguard their proprietary processes and formulations.

4. Communication Barriers Effective communication is vital in maintaining a successful OEM relationship. Language barriers and cultural differences can complicate interactions, leading to misunderstandings. Establishing transparent communication channels can help bridge these gaps.

Best Practices for Successful OEM Buying

To maximize the benefits of OEM buying for bentonite clay, manufacturers should adopt the following best practices

1. Thorough Supplier Evaluation Conducting comprehensive due diligence on potential suppliers is crucial. Assess factors such as production capacity, quality certifications, and customer reviews to ensure alignment with your company’s standards.

2. Establish Clear Agreements Defining user responsibilities, quality expectations, and delivery timelines in contracts can prevent disputes and foster a smooth working relationship. Clear agreements also help in accountability.

3. Invest in Relationships Building strong relationships with OEM suppliers can lead to long-term collaboration, better negotiation terms, and shared innovations. Regular communication and engagement foster trust and mutual understanding.

4. Continuous Monitoring Implement a consistent evaluation process to monitor the quality of the bentonite clay supplied. Regular audits and feedback can help suppliers improve their processes and maintain high standards.

Conclusion

OEM buying for bentonite clay manufacturers represents a strategic approach to enhancing product quality, reducing costs, and increasing market responsiveness. By understanding the benefits and challenges associated with this strategy, manufacturers can leverage the strengths of their OEM partnerships to thrive in the competitive landscape of industrial minerals. With careful consideration and proactive management, OEM buying can be a gateway to sustained growth and innovation in the bentonite clay market.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025