micro silica fume suppliers factory

Understanding Micro Silica Fume Key Facts and Suppliers

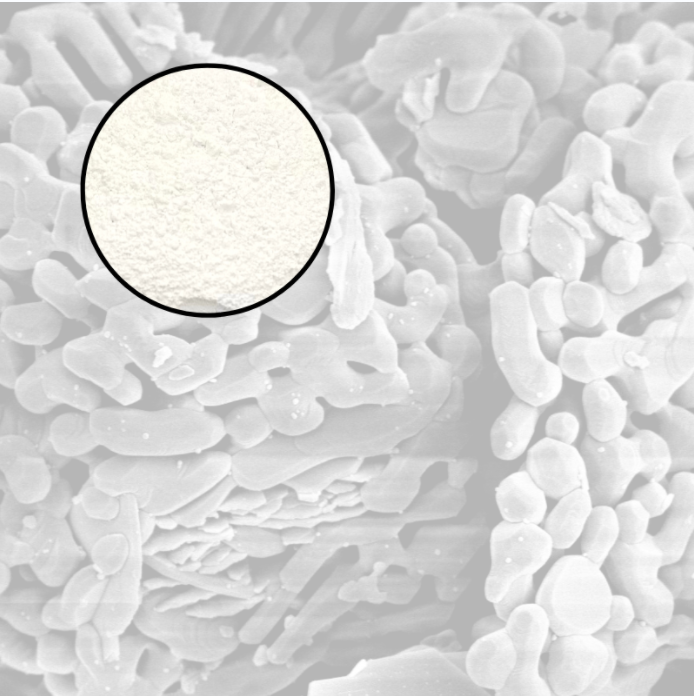

Micro silica fume, also known as silica fume or condensed silica fume, is a byproduct of the production of silicon or ferrosilicon alloys. This fine powder consists of spherical particles that are less than one micron in diameter, making it one of the densest and most reactive forms of silicon dioxide available. Its unique characteristics make it an invaluable additive in various construction materials, particularly concrete. In this article, we will explore the significance of micro silica fume, its applications in construction, and the role of suppliers and factories in this industry.

What is Micro Silica Fume?

Silica fume is created during the process of smelting high-purity quartz in electric arc furnaces, which leads to the generation of silicon and a significant amount of byproduct—silica fume. This material is often collected using baghouse filters from the flue gases of the smelting process. Although silica fume has been around since the 1970s, its applications have evolved over the years, and it has become an essential additive for enhancing the mechanical and durability properties of concrete.

Benefits of Using Micro Silica Fume in Construction

1. Enhanced Strength Micro silica fume significantly increases the compressive strength of concrete. When mixed with cement, the reactive silica in the fume reacts with calcium hydroxide, producing additional calcium silicate hydrate (C-S-H), which is responsible for concrete's strength.

2. Improved Durability It's well-known that concrete susceptible to various forms of degradation, including sulfate attack, corrosion from chlorides, and freeze-thaw cycles, can benefit from the addition of micro silica fume. Its dense structure fills voids in the concrete matrix, reducing permeability and enhancing long-term durability.

3. Reduced Shrinkage Incorporating micro silica fume can minimize the shrinkage of concrete, which is particularly beneficial in large structures where cracking is a concern. The filler effect it provides helps maintain the integrity of the concrete as it sets and cures.

4. Sustainability Micro silica fume contributes to sustainable construction practices. By replacing a portion of Portland cement, which is known for its significant carbon footprint, with silica fume, the overall environmental impact of concrete production can be reduced.

Applications of Micro Silica Fume

Micro silica fume is widely used across various construction projects. Some common applications include

- High-Performance Concrete Demand for high-strength concrete in structures like bridges, high-rise buildings, and pavements can be met efficiently with the use of micro silica fume

. Its superior properties help achieve high performance in challenging environments.micro silica fume suppliers factory

- Precast Concrete Products In the precast sector, such as for panels, blocks, and pipes, silica fume enhances strength and durability, making these products suitable for harsh conditions.

- Repair and Rehabilitation When repairing aging infrastructure, micro silica fume is often used in repair mortars and grouts. Its properties help ensure a strong bond and longevity of the repairs.

- Shotcrete In applications involving shotcrete, such as tunnels and underground projects, micro silica fume improves adhesion and stability.

Finding Reliable Micro Silica Fume Suppliers

When it comes to sourcing micro silica fume, selecting a reputable supplier is key to ensuring quality and consistency. As the demand for this additive grows, numerous suppliers and factories have emerged worldwide. Potential buyers should consider several factors when selecting a supplier

- Quality Assurance Ensure the supplier adheres to relevant industry standards and offers quality certifications for their products.

- Production Capacity Choose suppliers with adequate production capabilities to meet large-scale project demands.

- Technical Support A competent supplier should provide technical assistance, including mix design recommendations and application methods.

- Logistics and Delivery Evaluate the supplier's ability to deliver products promptly, especially for time-sensitive construction projects.

Conclusion

Micro silica fume plays a pivotal role in enhancing the performance of concrete and other construction materials. Its unique properties offer numerous benefits, making it a popular choice in high-performance applications. As the market for micro silica fume continues to expand, partnering with reliable suppliers and factories will be crucial for construction professionals seeking to improve their project outcomes. With sustainability and durability becoming increasingly critical in construction, micro silica fume is poised to remain an essential additive in the industry.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025